In today's fast-paced world, ensuring the safety and integrity of products is of utmost importance. EPE wads and washers, often overlooked components, play a vital role in this process. In this comprehensive guide, we will delve into the world of EPE wads and washers, exploring their applications, benefits, and why they are a must-have in various industries.

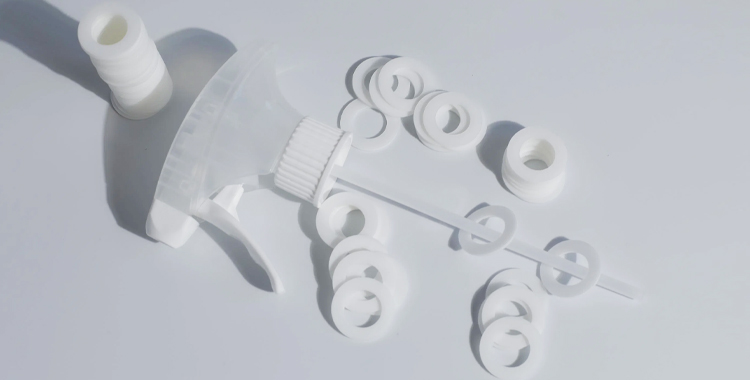

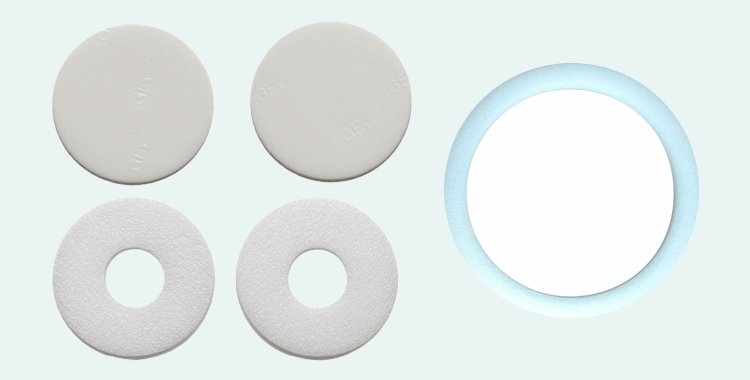

EPE, or Expanded Polyethylene, wads and washers are versatile and cost-effective sealing solutions. They are primarily used to provide a secure and tamper-evident seal to containers, ensuring the protection of the contents inside. EPE wads and washers are known for their excellent cushioning properties, chemical resistance, and low moisture absorption.

EPE wads create an airtight seal, preventing oxygen from entering the package and preserving the freshness of the product.

These wads provide clear evidence if a package has been tampered with, ensuring consumer safety.

EPE wads are resistant to a wide range of chemicals, making them suitable for various industries, including pharmaceuticals and food.

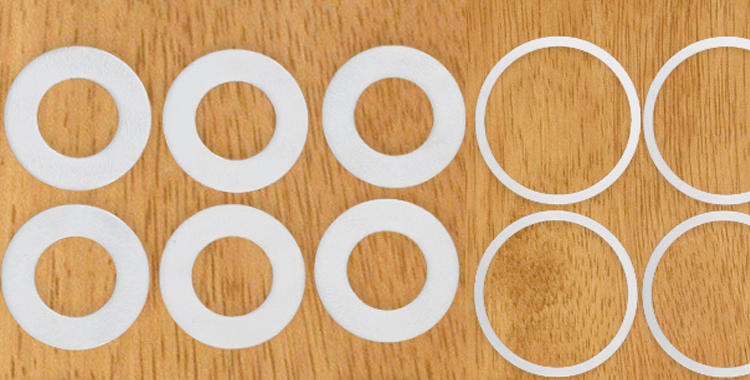

EPE washers act as a cushioning and sealing element, enhancing the structural integrity of the product's packaging.

They protect products from moisture damage, making them ideal for electronics and sensitive equipment.

EPE washers reduce vibrations during transportation, preventing damage to fragile items.

EPE wads and washers find applications across a wide range of industries due to their versatile nature and reliability.

In the pharmaceutical industry, the integrity of products is paramount. EPE wads ensure that medications remain uncontaminated and potent.

EPE wads are commonly used in food and beverage packaging to maintain product freshness and safety.

The delicate components of electronics are safeguarded by EPE washers, protecting them from shocks and vibrations.

In today's eco-conscious society, it's crucial to consider the environmental impact of materials. EPE wads and washers are environmentally friendly, as they are recyclable and can be reused in various applications.

Yes, EPE wads and washers are safe for food packaging. They are FDA-approved and offer excellent protection against contamination.

Absolutely. EPE washers are known for their thermal stability and can perform well in extreme temperature conditions.

Yes, EPE wads are recyclable, contributing to a more sustainable packaging solution.

EPE wads create an airtight seal, preventing oxygen from entering the packaging and ensuring the longevity of medications.

Yes, EPE washers are available in various sizes and shapes to suit different applications and industries.

EPE wads and washers may be small components, but their impact on product safety and integrity is immense. From pharmaceuticals to chemicals, these versatile sealing solutions are essential in various industries. Their ability to protect against tampering, moisture, and vibrations makes them indispensable. Moreover, their eco-friendly nature aligns with the growing emphasis on sustainability in manufacturing. For more information and access to top-quality EPE wads and washers, click here.