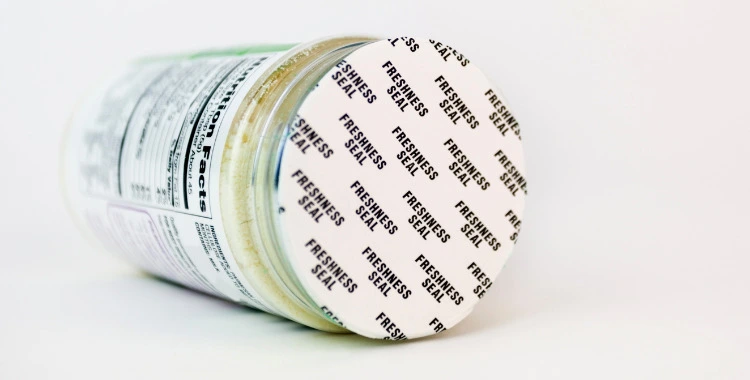

Induction sealing is a straightforward procedure that involves closing the mouths of glass/plastic bottles with aluminium foil to improve the freshness and shelf life of the product inside. This is done by inserting the seal inside the cap and running this bottle with an induction heat sealer before filling up the final product. The bottle's contents are safe from contamination and spills and pilferproof by sealed induction wads. Due to the power of Holography, the induction seals have tamperproof properties and are more secure and efficient than ever. The various kinds of induction seals will be visible as the assurance of quality and uniqueness once the cap is opened to consume the content like lubricants and other liquids.

The design of an induction seal is relatively easy. Induction seals, in their simplest design, consist of three primary layers:

To stop leaks, many industrial facilities require chemical liquids to be sealed before the product is shipped to prevent other dangerous chemicals from spilling onto other products.

These induction seals are used, and harmful contaminants are kept from leaking through food ingredients, thus extending the shelf life of some food items.

The process by which induction wads are made aids in stopping the finished product from getting damaged. It is observed that the majority of pharmaceutical companies buy induction sealing liners to avoid any damage to their products.

Metro International LLC is one of the top manufacturers of induction wads and seals, as they contribute to the product's longevity by permitting lighter weights for bottles. In the end, the entire package is dependent on the quality of the induction foil seal to provide the highest level of security.

Induction wads and seals are used to seal containers and protect their contents from contamination or degradation caused by exposure to moisture, air or any other undesirable impureness. This is why the applications of induction sealing wads are used extensively by a wide range of industries. Metro International has one of the best induction wads and seals in Dubai. No matter what industry you are in, induction seals are essential for packaging your product. If you want to learn more about it, you can contact our professionals, and we at Metro International can assist you.